Coming from a background of aircraft modeling, I’ve never really thought much about adding decals to a model. While there are many nuances to doing so successfully, the basic premise – dip it in water, slide it on the model, let dry – is somewhat… cut and dry. (Pun intended. 😉 )

When I’d made a “genre jump” in the latter part of 2017 to start adding Gunpla, Warhammer, and other scifi builds into my mix of projects, I was a bit surprised to encounter so many folks who were not very comfortable at all with adding waterslide decals to a model. Yet the number of times I saw mentions of never having added decals to a model – especially Gunpla – and the misconceptions about the difficulty of it, led me to a simple conclusion…

Time for one more random guy to write about how to apply decals! 😀

Waterslide decals are essentially small printed images that when soaked in water will come loose from the backing paper, and can then be applied to the surface of a model. Simple enough. Still, there are some basic bits of knowledge that I think will help you along your quest for decaling goodness.

The essentials

Now, anytime someone tells me a thing is simple, I feel a bit like a proctologist driving to work… you know there is a “but” coming pretty soon.

(That was pretty clever, right? I just made that up all on my own!)

First, you need the right tools. While you may not use all of these, or perhaps use things in place of or addition to these, I’ve found that my decaling process goes nicely with these accoutrements.

- Some pieces of paper towel (I show only a small piece in the photo)

- Cotton buds

- Toothpick (or cocktail stick, depending on your country of origin. Consult local laws for full details…)

- Hobby knife with a new blade

- Some older paintbrushes

- Tweezers

- Decal setting prep (I use Micro Set)

- Decal softening solution (I use Solvaset)

Finally, you need water. But not just any old water will do. Decals like warm water… hot even. But you may be pondering “how do I keep the water warm?” Ponder no more! I will show you my secret weapon!

OK, it’s not really a secret. And as a weapon, it’s a bit lame. (Hands up, or I’ll warm you slowly…) Still, a coffee mug full of warm water will do wonders for your decals. And a simple coffee warming plate will keep that water warm. I start by warming my water in the microwave first. Most coffee warmers are not made to heat up water, just to keep it warm.

I’m not sure what the exact temperature is. I fill the mug mostly full, pop it in the microwave for 90 seconds, and use that. If I had to describe it, it’s hot enough for a satisfying cup of tea or coffee, but not so hot you wince at it each time you take a sip. (How is that for precision?)

With those tools in place, you’ll need two other critical elements.

You will need your handy dandy decals, and a model to put them on.

For the model, I recommend giving it a good gloss coat before applying decals. While there are some instances where this is not required for smaller decal application, I generally recommend applying decals over a gloss coat. Especially if you’re new to the process. I prefer to airbrush my gloss coats, using Future floor polish. (Or Pledge, Kleer, or whatever else it may be called.) Certainly modeling specific gloss coats work. The main thing is to get a good gloss coat on. And I’d suggest applying it to the whole model, or in some situations, at least the whole panel to be decaled. While you can matte coat it later to dull it down, there will be a definite color shift between the glossed and unglossed surface.

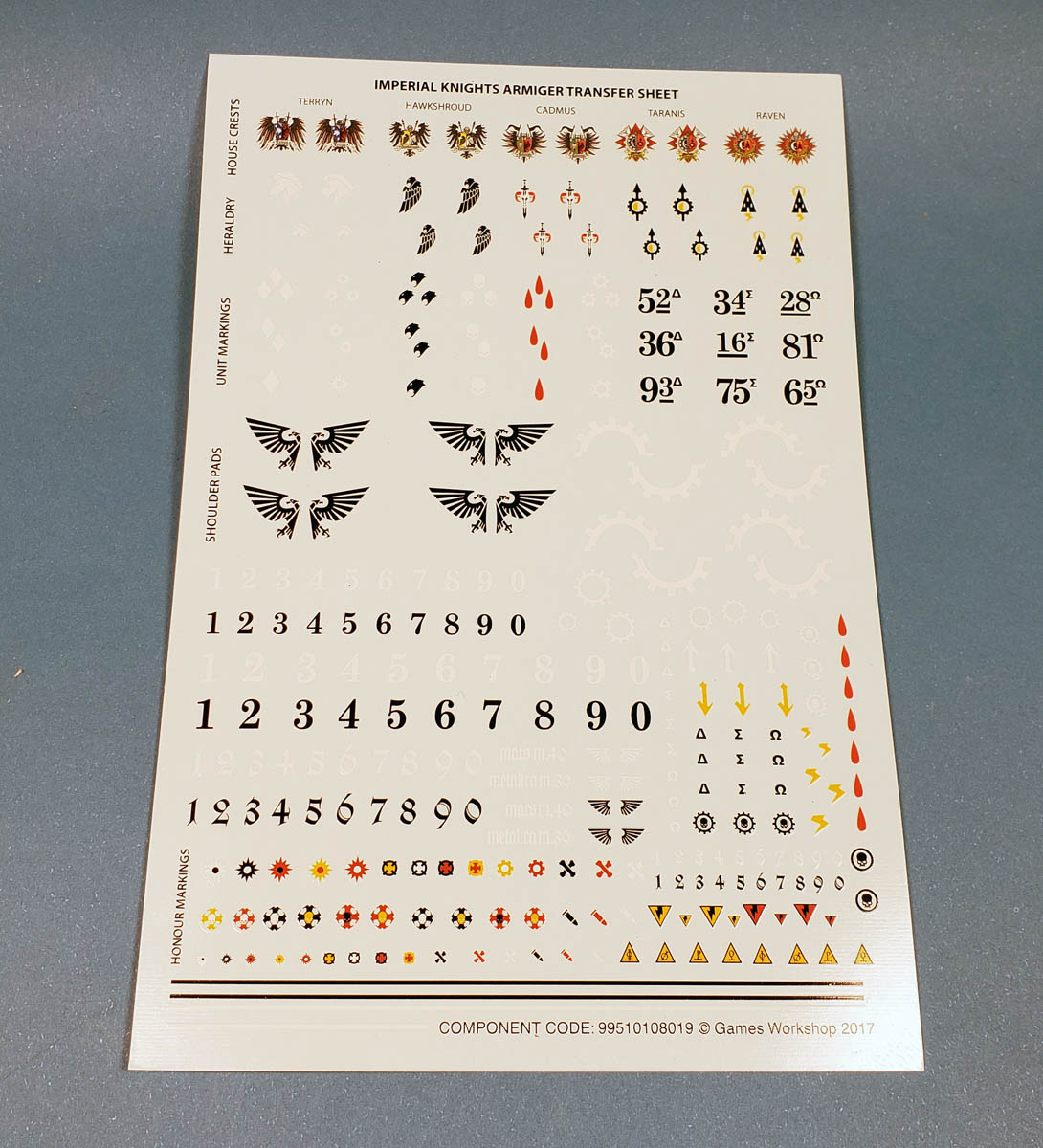

For this example, the victim model is Citadel’s Armiger Helverin, from the Warhammer 40K range. However, the basic principles shown here work for any genre.

Basic Application

The first step is to cut out your decal from the decal sheet. For this, I use my hobby knife. You should note the clear edges of the decal film, which will project slightly past the colored printing. This is what holds the decal together. On very high quality sheets, such as those printed by Cartograph, this edge will be incredibly slight. On these Citadel decals, there is a bit more showing, but not enough to worry about. On some brands, the decal film may extend far outside of the printing. In those cases, I cut the decal as close as I can to the printing without slicing into the decal.

One trick I do like to employ is to leave myself a bit of a “grab handle” on one side, so I can grip the decal paper with my tweezers. If this will leave a wide bit of decal film on one side, I just make a thin slice in that area that is just deep enough to cut through the film, but not all the way through the paper. (This works too if you have some home printed decals where the entire surface is essentially decal film.)

(Apologies to Paul for the lack of manicure… 😉 )

While you can place decals directly down on the glossed surface, for most decals, I prefer to apply a bit of setting solution. My brand of choice is Micro Set. It smells strongly of vinegar, and many modelers do simply use vinegar. There are of course alternative brands, and you can also use plain water. I’ve also found that if I see a particular set of decals is prone to “silvering” (more on that to come) I’ll even use a dot of Future.

In any event, I place a few drops of setting solution with an old brush where the decal is to be placed.

Next, grab your tweezers, and dip the decal fully into your warm water. Give it a count of 10. No more, no less. Ten shall be the number thou shalt count, and the number of the counting shall be ten.

Remove it from the water, and set it on a piece of paper towel. Using a clean brush, test it a bit to see if it’s loose. The warm water will help loosen most decals up really fast. If it is not loose, leave it be for about 30 seconds. If after that time, it’s still not loose, use your brush and apply more water to it.

Never, ever, ever, never dip the decal back into the water. Quite often, the force of the water hitting the decal will lift up the edge, and it will fold back on itself. A folded up decal is never good, and may cause all forms of thrashing about and questionable word emittance. (Trust me on this…. I actually ruined a decal doing just this as I took photos for this bit, even though I know better!)

One it is loosened, pick it up with the tweezers by the backing paper- this is where the grab handle mentioned earlier comes in handy – and hold it flat to the surface where you will apply it. Using a toothpick or paint brush, gently slide the decal on to the model’s surface, right on top of the setting solution.

(This normally requires two hands, though for the photo, I was holding the camera. Because the tripod was aaaaaallllll the way across the room. Because lazy.)

Once the decal is in place, use a toothpick or paint brush to “nudge” it around to the correct positioning. If the decal is difficult to move, apply a bit of warm water with a paint brush. Don’t soak the surface – you’re just wanting to give enough fluid for the decal to “float”. Patience is the key.

Once it is generally in place, use a cotton bud or piece of paper towel to wick away the moisture around the decal. Make any final adjustments as required, repeating the process until the bulk of the water is soaked up, and the decal is in place.

Grabbing your cotton bud, you’ll now want to gently push it into the center of the decal, using the side of the cotton bud. Slowly begin to roll the cotton bud along towards the outer edge of the decal. The idea here is to force out the water from underneath. Even though it looks to be lying flat, you’d be surprised how much water is underneath that little decal. Keep gently working your way around the decal, until you get no more water out from underneath. Always work from the interior of the decal out. Reversing that may cause the edge of the decal to roll up with your cotton bud.

A Time Out To Discuss Silvering

Sometimes you may not get all of the water out from under a decal. When the water eventually dries, this leaves a bubble. If it’s under a colored portion of the decal, you may never see it. However, if it happens under the clear film portion, this may only show up after matte coating, and will appear as a “silver” bubble. In certain lights, it can really look bad.

The first step in preventing this is a good gloss coat for application. A smooth surface leaves fewer areas for water to be trapped. The setting solution also helps by making sure the whole decal surface sticks cleanly. The process of pushing the water out with a cotton bud further helps remove any moisture (or air bubbles) from underneath.

Still, doing all of that does not guarantee a complete absence of silvering, especially with cheap decals. Keep reading for what to do when there is silvering….

Back To The Decaling

With the decal firmly in place, I next apply my decal softening solution. For this, make sure you use a brush that is set aside for only decal softening solution. Unlike the surface prep solution, products like Solvaset (or Micro Sol) will dissolve the decal if you’re not careful. But that’s good – that’s what they are supposed to do. Still, you want to control it.

The way I apply the Solvaset is to quickly dab on the fluid across the whole decal, allowing it to go just enough over the edges to get a good seal all the way around. Don’t flood it, but don’t skimp on the application either. Once you have it on there, DON’T TOUCH IT.

No matter what. Treat it like a hot stove.

The decal softener is doing just that – making the decal soft. This will cause it to conform to the surfaces very nicely, and even pull down into any recessed areas, or surface detail. (More on that…)

Depending on the softener you use, it may cause the decal to wrinkle up. Sometimes horribly so. Even then – LEAVE IT ALONE. Trust me. If you try to nudge it around at this point, you’ll only smear the decal. You can go on applying other decals, but just avoid touching any that have the softener on them.

Tip: I like to decal one section of a model, say the left fuselage half on an airplane, and then apply the softener to all the decals at once, then set it aside for an hour or so. I can then tackle the right side, upper wings, etc.

Once the softener fully dries (this can take a few hours), your decals are now firmly in place. I like to allow an overnight drying at minimum, and then I apply another gloss coat. This will seal the decals in and protect them from damage by later weathering steps.

With all of that completed, our Armiger Helvering is ready for me to mess up something else finish it up.

(Yes… I know… I weathered before applying decals. Got ahead of myself. If you do the same thing, don’t panic. Just go back over the decals with the same weathering seps, and you’ll be good to go. I normally do weathering after decals.)

Slightly More Advanced Application

On many models, the decal may need to be applied over panel lines, raised detail, etc. While the particulars will vary from model to model based on the surface and the decal, you can make sure the decal is as close to “painted on” as possible with this simple step.

Once the decal is fully dry, but prior to a final gloss coat sealant, grab your handy hobby knife, with a fresh blade in it. Carefully slice through the decal along any panel lines or recessed detail. (I switch to my 1/48 Trumpeter L-39ZA for these photos.)

For things like access panels that have curved lines, you may need to use the blade tip to just poke small holes along the area of the curvature. Around raised detail, carefully make small cuts just along the edge of the detail. Work slowly until you get used to how the decal will react. Some slice nicely, some will want to tear.

Once you’ve made the appropriate cuts, make another application of your softening solution, but only along the freshly sliced areas. (It won’t hurt to get the other areas, it’s just wasteful…) Let that fully dry.

This process should “pull” the decal nicely into recessed detail, and help it conform to raised detail. Occasionally, you may need to follow up with another application if it did not fully work along the entire section. Just follow the same steps through, until you have a nicely applied decal.

With all that completed, you should have some great looking decals. (If not, I blame…. you know who you are. 😉)

Final Thoughts

- If you do see silvering in your decals, there are two primary ways I deal with them

- Softening Solution – I like to use a sharpened needle to poke small holes in any bubbles, and apply softening solution. If an area is larger, the hobby knife can be used to make small slices.

- Paint – If after trying the above step does not fully work, I may use a dot of paint to cover it up, but only if I can get a perfect match to the underlying paint.

- Make it weathered – a final move is to make that area appear weathered, via chipping, stains, etc.

- Wash off the decal softening solution – some folks like to use a water damped paper towel to gently wipe away any decal softening solution stain that may appear after everything dries. You can easily check if this is needed by holding the model up to the light, and seeing if stains are apparent.

- For longer decals, such as stripes, or decals that must conform to a curved surface, it can often work better to carefully cut the decal apart. Of course, this means that aligning it properly during the application process is crucial .

- Paint touch-ups and/or weathering can help close small gaps in decals, or conceal decal damage. Just use colors that match as closely as possible.

- If you have not used waterslide decals before, be prepared you may have some mishaps. I’ve used them on hundreds of models, and still run into issues from time to time. Use each instance as a learning episode. Work slowly and carefully, and pay attention to what’s going on. In most cases, you can logically deduce what works and what does not.

Applying decals will give any model a great look. Doing this process well really sets off your work. Give the steps outlined above a try, and if you have any problems along the way, perhaps try alternate products, or different approaches. As with any skill in the hobby, everyone arrives at their own special way of doing it.

Whatever you do, just have fun with it!

Leave a Reply