Part of my growing and learning in the modeling hobby over the last decade has been a constant refinement of processes and techniques. When I first started, I tried a few basic things early on, but with each new build, I’d notice some additional little bit of something that could be fine tuned. I’d ask questions, search the Web of the Worldwide Interthing, and on rare occasion, just sort of figure it out.

One of the items that perplexed me for a while had to do with the matter of sealing up hairline cracks along a glued join. It might be a wing, or a separate panel, or whatever. It’s not so much that a part might not fit well, but simply that in places, the fit was not perfect – which left a small gap.

Bigger gaps were easier, of course. Those I’d fill with stretched sprue, or a modeling putty, sand it down, and rescribe it as needed. But for areas that were supposed to remain as panel lines, and the gap was very tiny, the use of modeling putty and all that sanding seemed a bit of overkill.

I was describing my dilemma to a friend who was much more of an experienced modeler. He passed along a little bit of info that at the time seemed like a good solution. Little did I realize how good – I’ve since used it on virtually every build over the last decade.

Defining The Target

If a model is reasonably well engineered, a builder can expect most things to fit with some semblance of precision. If you’re building a Tamiya, Eduard, or Bandai kit, it’s generally accepted everything will fit very nicely. Other brands do an OK job of it, but not so bad as to make a kit unbuildable. (Admittedly, a few can be awful… not naming any names. Special Hobby.)

As I previously mentioned, some gaps will of course require proper fillers, or pieces of sprue. And quite often a gap simply needs to be sanded smooth. Additionally, many gaps can be avoided altogether with good parts preparation before anything is even glued together.

However, many model makers logically break down parts along panel lines. This can help make assembly easier by attempting to hide the joins. If all works well, the join will be clean, no sanding will be needed, and surface detail is preserved.

In many cases, though, imperfections in the casting, parts, misalignment, or even overzealous sanding and cleanup of sprue connection points can leave a part slightly uneven. The result is that when glued together, a small gap may be left.

Now, the method I will be describing is NOT for larger gaps, or any gaps that require some strength of structure. For instance, a gap along the length of a wing-to-fuselage join needs addressing (generally) with a bit of plastic and proper cement, because the wing itself needs to be firmly attached to the model.

Additionally, if a gap is too much wider than the width of the panel lines around it, it will often need to be filled with modeling putty.

However, if the gap is thin, or in a fairly recessed area, I have a quick and simple method I like to use to get a model sorted out and ready for priming and painting.

The Name Is Surfacer. Mr. Surfacer.

If you’ve not used Mr. Hobby’s Mr. Surfacer, trust me – you want this in your bottles of stuff. It comes primarily in three thicknesses – Mr. Surfacer 500, 1000, and 1200. It’s a very thick, gray…. well…. goop. The 500 variety is thicker than the 1000, which is thicker than the 1200. It can be thinned with Mr. Color Leveling Thinner and airbrushed, or it can be brush painted at full strength, or thinned. It dries firm enough to be sanded, though it is not as brittle or solid as modeling putty. It will shrink a bit over a few days or even weeks, so it’s not the perfect gap filler for everything. However, for filling cracks as I’ll be doing in this blog entry, it is perfect.

I generally prefer to get Mr. Surfacer 500, as it’s much easier to thin it than it would be to thicken the 1000 or 1200 varieties.

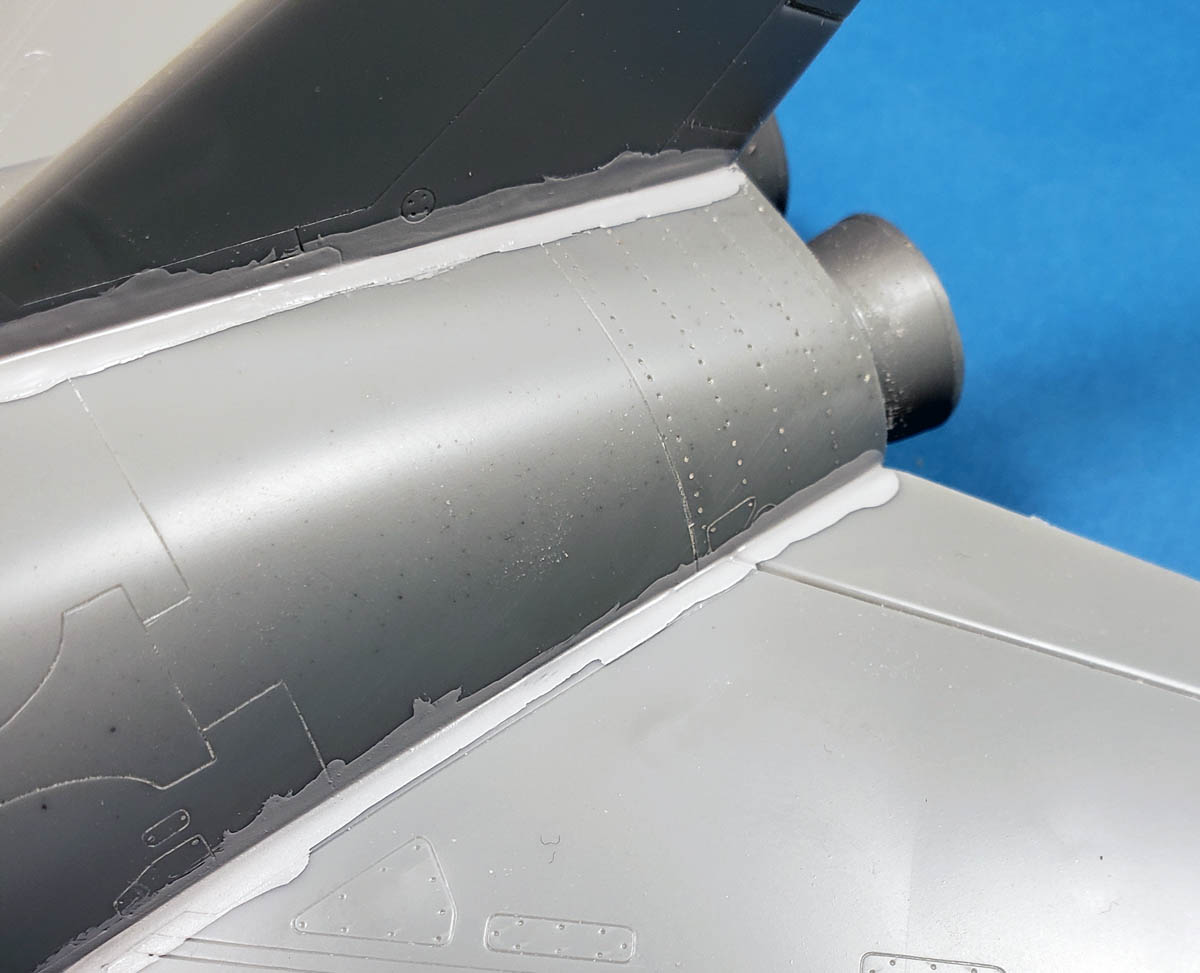

The victim for today’s demonstration is a Hasegawa 1/72 Jet VTOL from the old Ultraman series. As with most Hasegawa kits, the fit is generally good. However, there are a few gaps and cracks here or there. So closing those up will be needed before it can be primed.

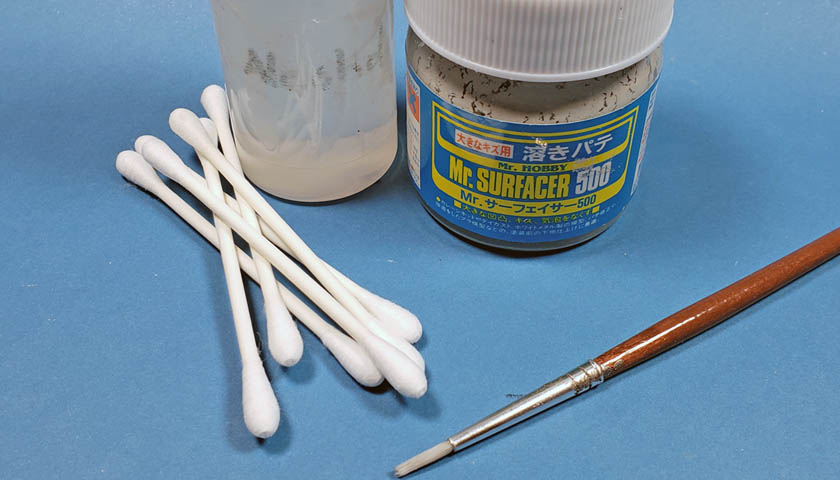

My tools for today are simple: My bottle of Mr. Surfacer 500, an older brush, some cotton buds, and some isopropyl alcohol. I use the 91% stuff, but if you have anything under that, it should work just fine. I like to keep my alcohol in a small squirt bottle, as it makes pouring it much easier that trying to use the larger bottle that it normally comes in.

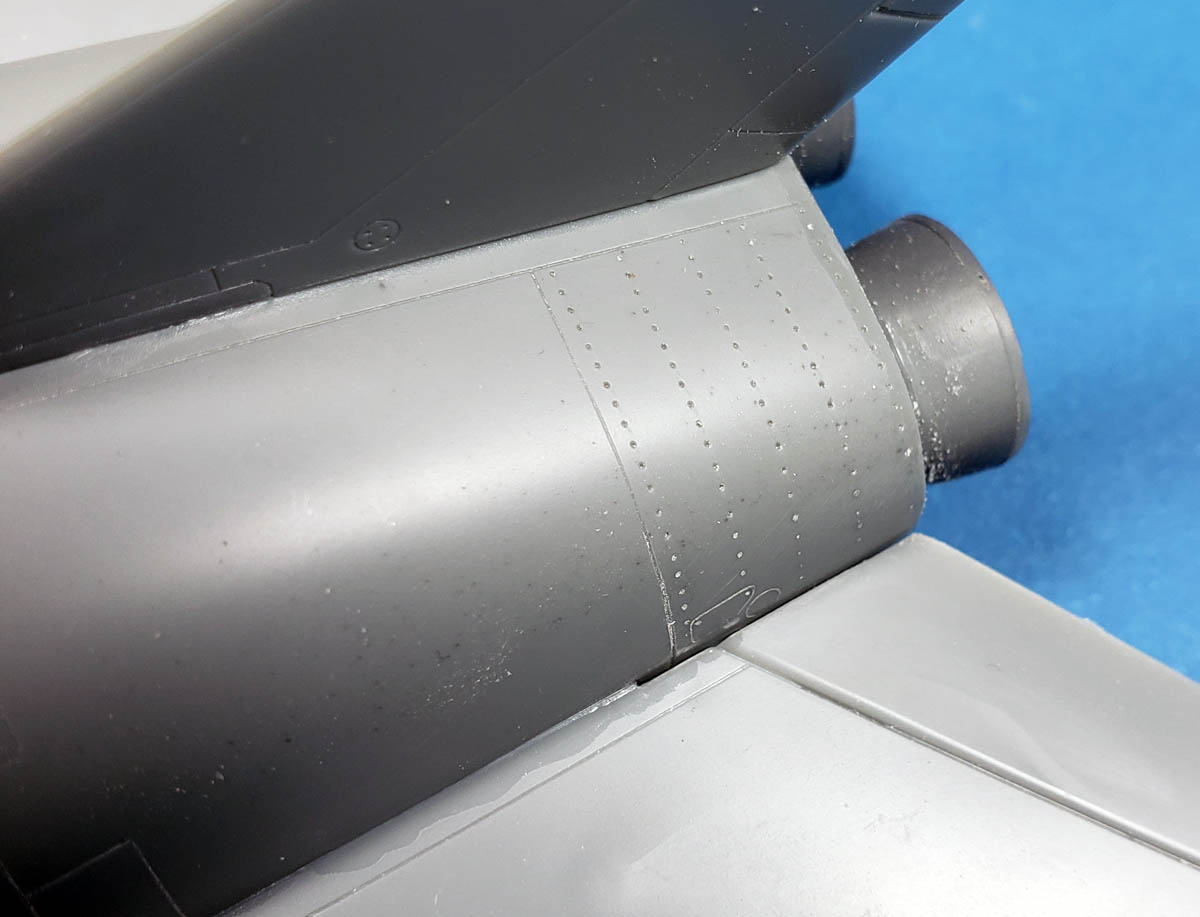

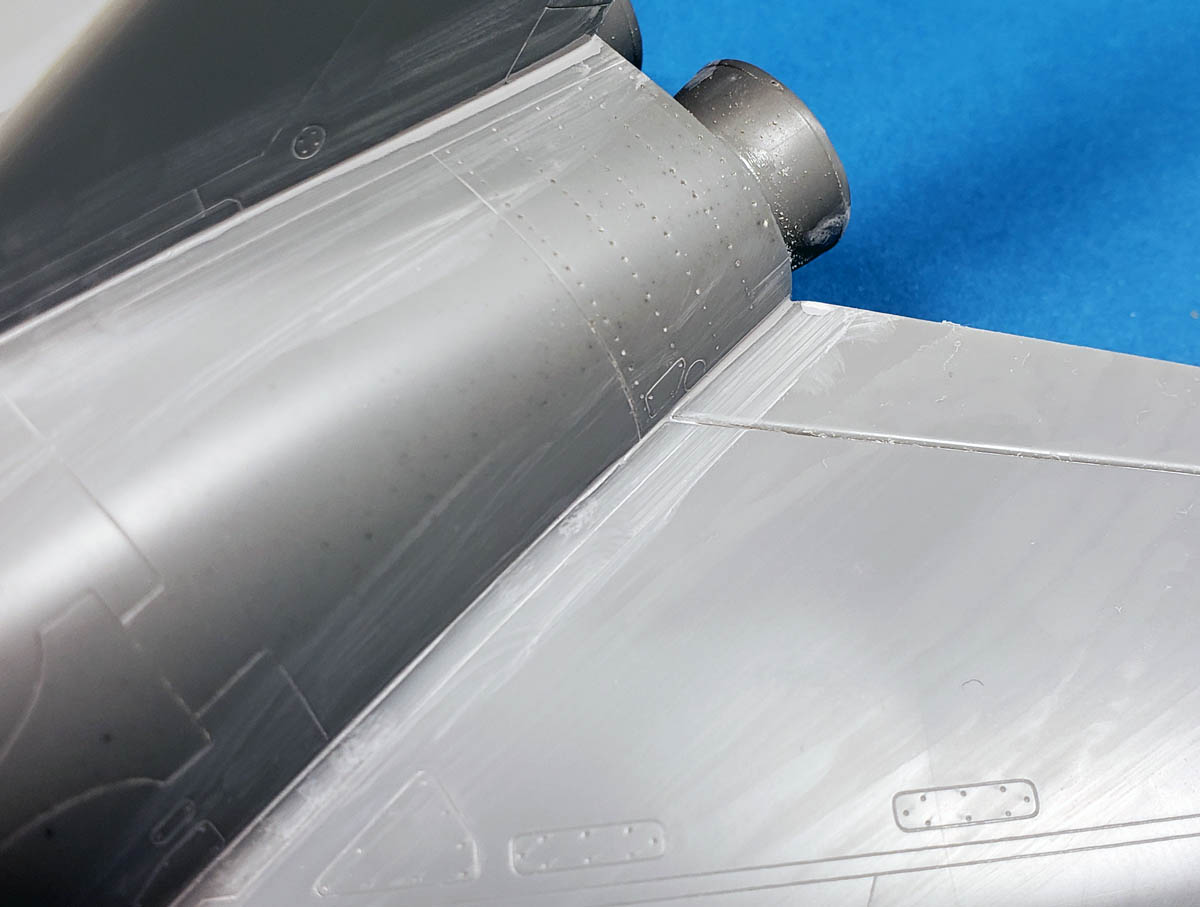

Here are three areas I wanted to focus on for the demonstration- where the vertical stabilizer joins the fuselage, a gap along the aft wing, and another hairline crack where the large clear part joins the fuselage. Each is a bit different. The stabilizer join will look OK if it’s not perfectly flush, but it’s a fairly deep recess. The wing gap area is a proper gap, but not wide enough to warrant filler. And the canopy part has a hairline crack, though there is a bit of a nubmark that may be a problem.

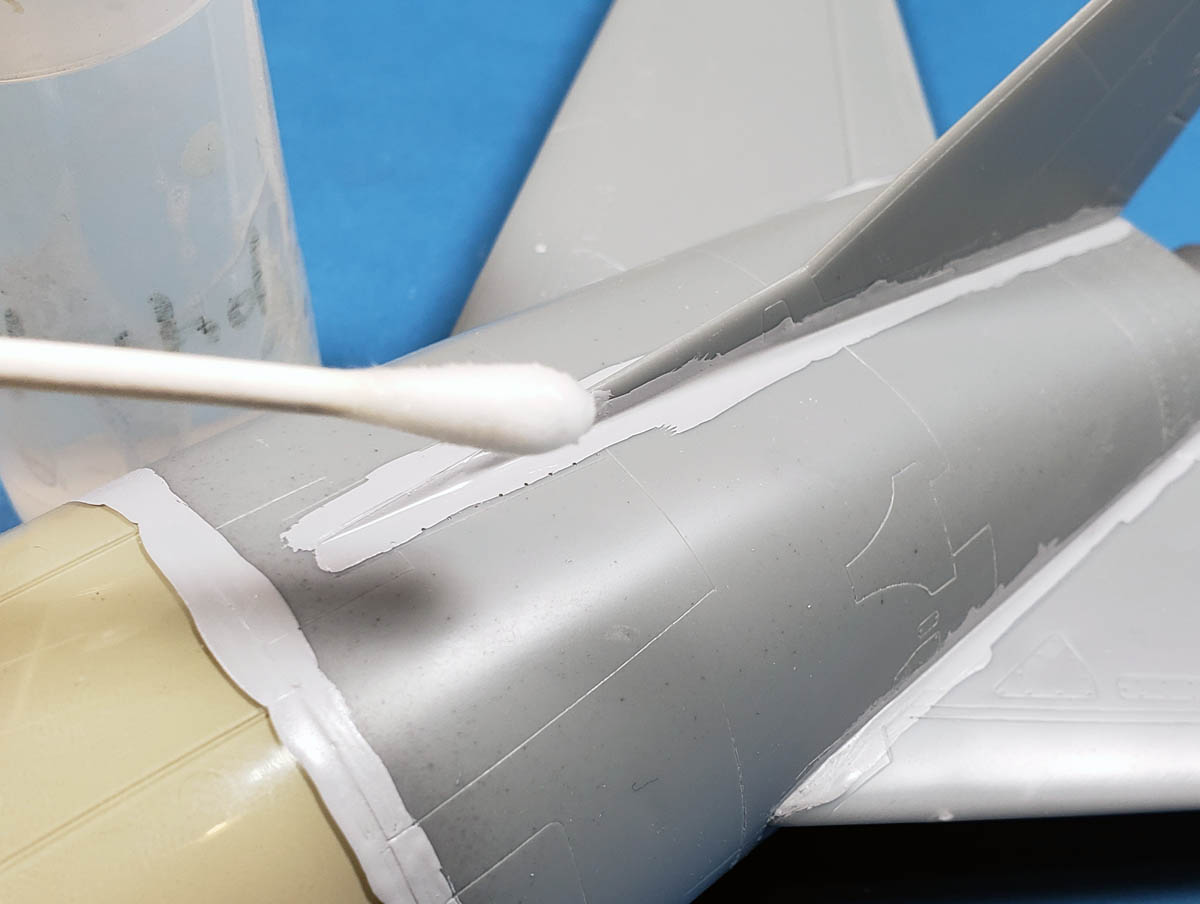

The first step is to simply paint on the Mr. Surfacer 500. I’m not particularly neat about it. It’s OK to glob it on rather thick, even if it gets into some of the surrounding surface detail. Sometimes it may take a few passes to fully fill an area. The idea is to get enough in to make it look like a natural panel line, and blend in with the other detail around.

Even though it’s fairly thick, Mr. Surfacer paints on without a problem. It doesn’t dry up immediately and “tear” like Tamiya paints do if brushed on. It goes on fairly wet and glossy, but dries to a bit more of a satin finish. It will also level out some.

If you paint on the first pass, and some sinks in a bit, or further gaps open, just add a bit more. However, if a bubble forms in an area – leave it be for now.

I don’t generally wait a long time to let it dry, often moving on to the next step as soon as the Mr. Surface is dry to the touch. Even if it’s a bit tacky, it’s generally OK to proceed. As you try this technique more, you’ll find the “sweet spot”.

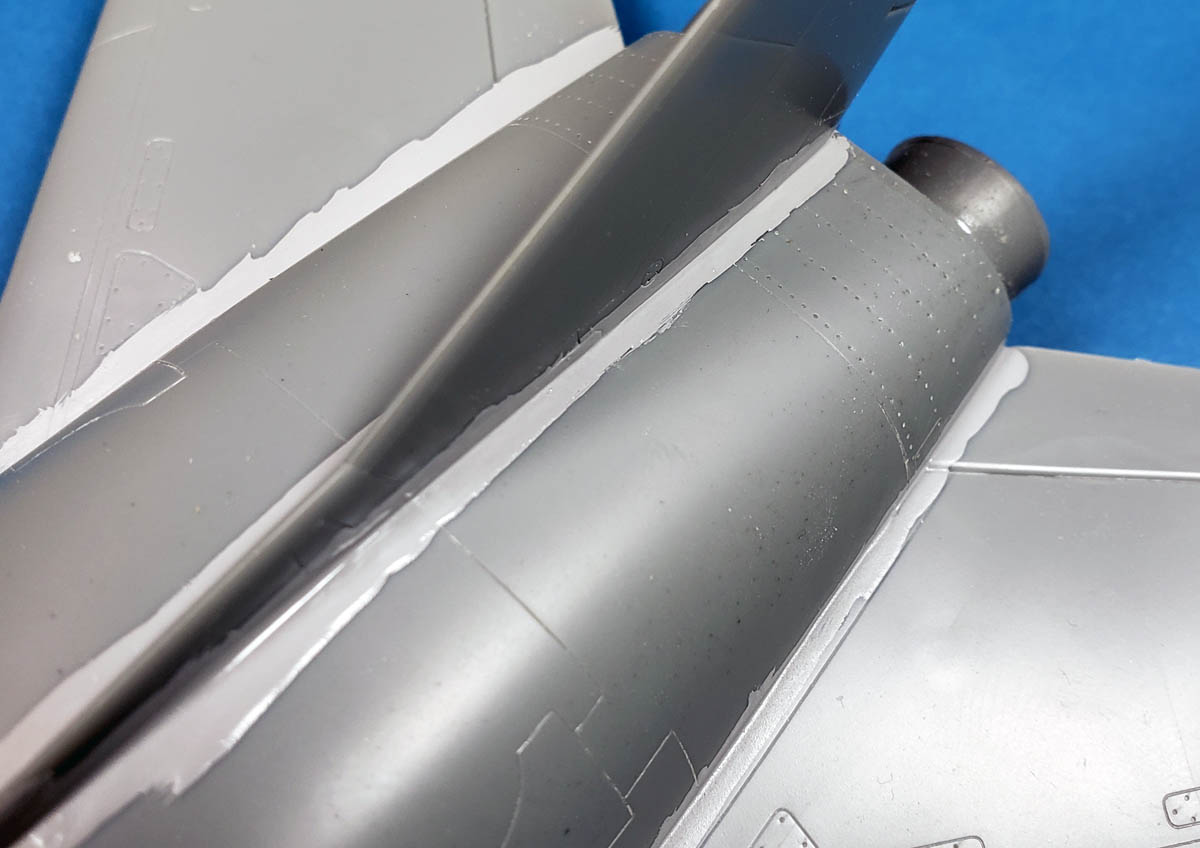

The next step is why I like this method so much. It’s so simple. I grabb a cotton bud, dip the end of it in my alcohol, and proceed to start rubbing away the excess Mr. Surfacer. If possible, I go across the Mr. Surfacer, not in the direction of the panel line or join. However, in some instances, you must go with the join, as with the vertical stabilizer join. Because so much of it is recessed, it works. Again – experience will help you refine this over time.

The motion to use is your old basic “rub back and forth”, though I do like to slowly twist the cotton bud as I work.

The alcohol will remove the Mr. Surfacer, but it’s not so “hot” that it will damage the plastic, or pull it up from the gap being filled. It will leave a bit of a mess, but for now, don’t worry about it. (More on that later.)

Keep going over all the areas that you have applied the Mr. Surfacer to. It will take quite a few cotton buds, though, depending on the size of the model and the surfaces being treated. As more Mr. Surfacer comes off on to the cotton bud, it will begin to build up. (That’s why I mentioned rotating the cotton bud…) Additionally, the alcohol will begin to dry up. I simply dip the other end of the cotton bud in alcohol, or switch to a new one. Again – the more you do it, you’ll figure out at what point it’s “right” to switch to a clean cotton bud.

In a few areas, you may not have applied enough to “stick”, or if the underlying Mr. Surfacer wasn’t dry, it may pull up. No worries if that happens, though. Just finish the job at hand, and go back and re-do the areas that still have cracks.

Also, I’d mentioned that if bubbles form, leave them be. In doing this over the years, I’ve noticed that on some models, air seems to want to escape from the areas I’m sealing. Instead of constantly fighting it, I just let the bubbles form. When I go back over it with the cotton bud, it will open up as a gap. I can then later go back an redo that area too, and it seems to seal fine.

I have waited as long as 24 hours to remove the Mr. Surfacer, but it takes much more effort at that point. Normally, I wait anywhere from 10 minutes to an hour. (About the time I need to take a short nap! 🙂 )

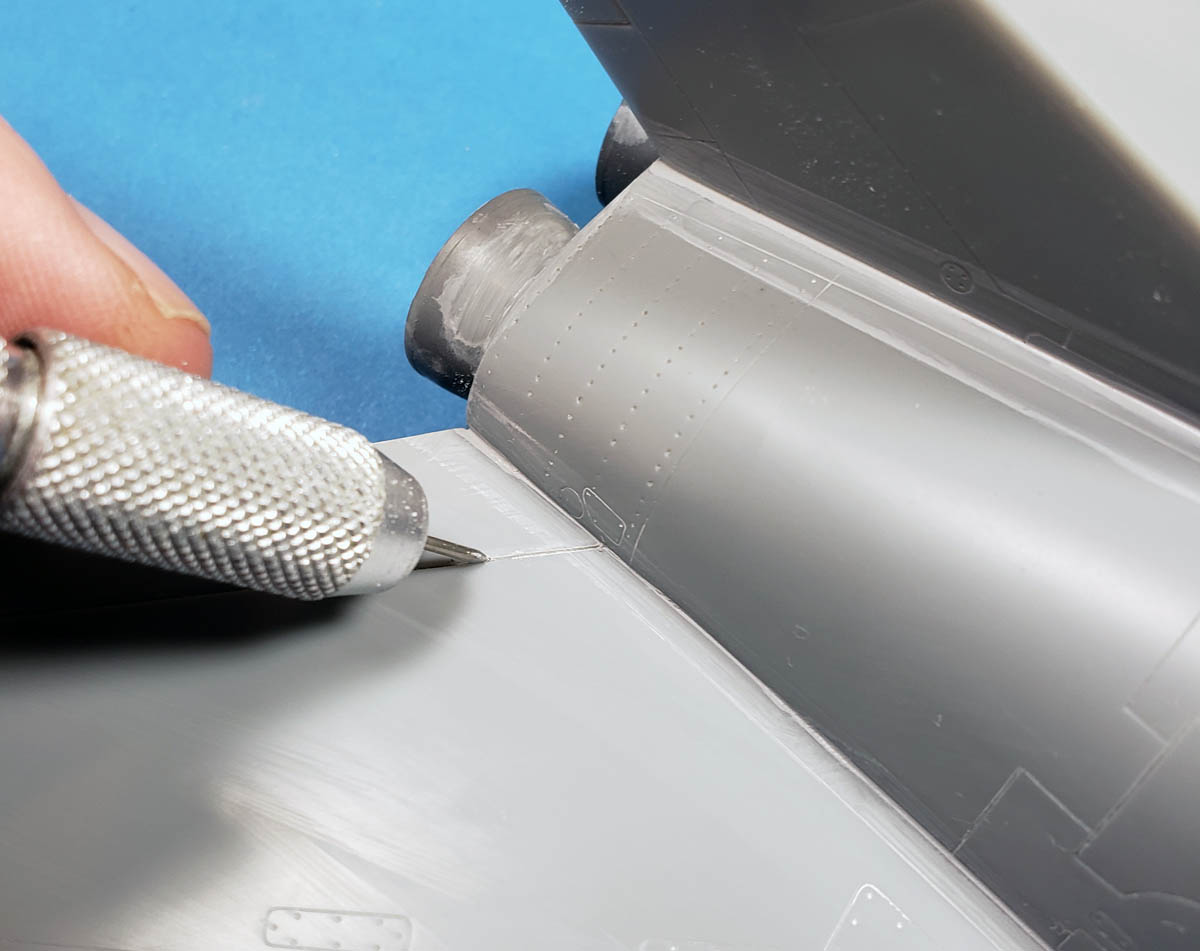

Once all of the excess Mr. Surfacer is is wiped off, and any problem areas have been refilled, you’ll probably notice that there is quite a bit of staining. Generally, this is not thick enough to create any problems, and can be primed over with no issues. (Remember- Mr. Surfacer is a primer also!) Also, some areas of recessed detail may have a bit more Mr. Surfacer in them than you’d like. Both issues are easily addressed.

For the excess, just grab a bit of paper towel, dampen it with alcohol, and wipe the surface clean. The excess will come right up. Do be careful about being too forceful over any places you want the Mr. Surfacer to remain. For recessed detail cleanup, I generally use a sharpened sewing needle mounted in a pin vise. It’s perfect for gently cleaning away excess filler. If you’re concerned about making a panel line too deep in cleanup, a sharpened toothpick works well too. It cleans up the Mr. Surfacer, but won’t dig into the plastic.

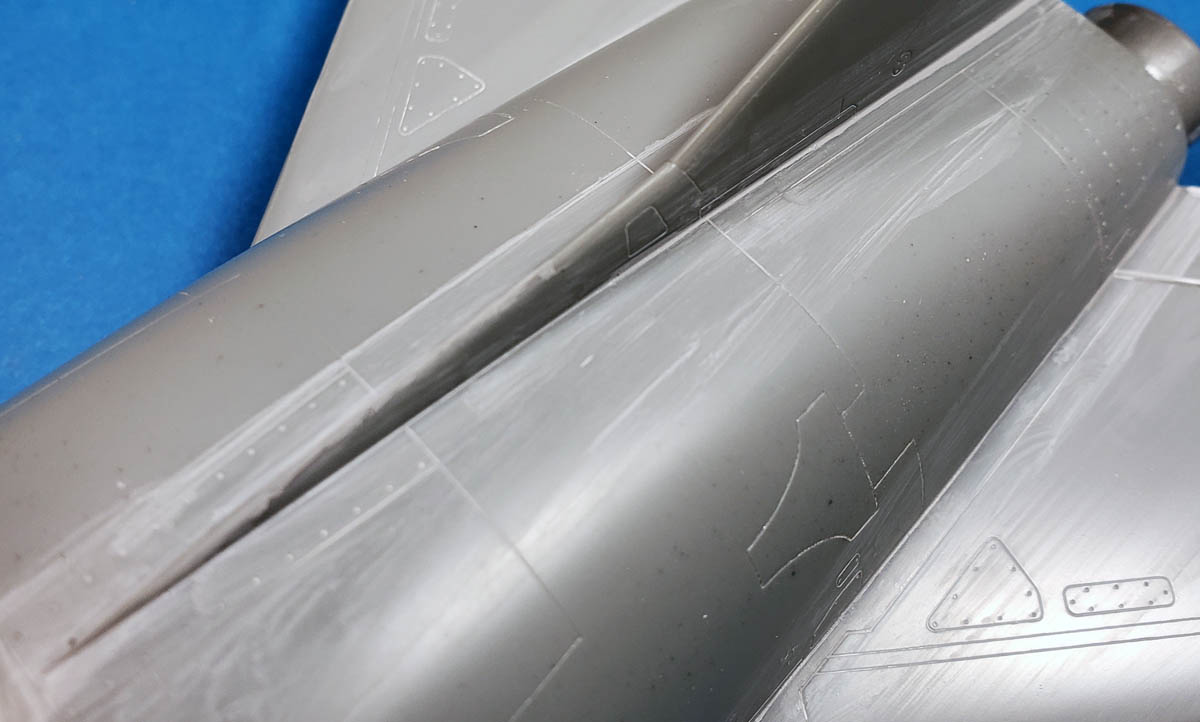

Once all the cleanup is finished, you should have your model ready for priming. As you can see in these final photos, the vertical stabilizer area and the wing gap are good to go. The hairline crack along the canopy join is also nicely sealed, but the photo does show that in some places, this technique cannot smooth everything out. I’ll need to mask and isolate that one small area where I was a bit sloppy in my part removal.

Mr. Surfacer is a great tool to keep on your workbench. It’s not only perfect for the gap sealing method described here, but can be used as a primer, for texturing a surface, and for smoothing out scratched areas. I’ve even mixed it with paint, and used it to bond canopy parts in place. You can clean your brush in Mr. Color Leveling Thinner, alcohol, or lacquer thinner. It can be a bit tricky to airbrush, so experiment with that a bit. If you plan to spray it, consider getting a bottle of the Mr. Surfacer 1200. While it will still need to be thinned, it won’t require near as much thinning as the 500 variety will. (And always wear your respirator!)

With all the gaps sealed off on my Ultraman Jet VTOL, I just need to address a few areas with filler and sanding sticks, and it will be ready for priming and painting.

I just hope no monsters show up in the meantime. Otherwise the Science Patrol may have to drive in to get to battle!

Leave a Reply